Q&A with Andrew McDougall on the WASZP latest news…

Andrew, can you update us on what has been happening since the last status report at Christmas?

As we mentioned in our last update we’ve been working hard on the rig and have gone back to the cambered sail.

Not only do we now know that this is our only performance option, we have also improved it dramatically since we first started working on that style of rig. It’s now much more like our latest Mach2 sail - just a little bit more powerful. We have also slightly increased the size for the large sail to 8.25 sq. metres.

We have made new camber inducers for the bottom battens to match the larger mast diameter, which are working really well. The sail is made with similar materials to the KA Sail moth sail although we have gone with slightly softer materials in the luff panels to give us a more user-friendly sail that rotates better and has increased reaction to downhaul tension.

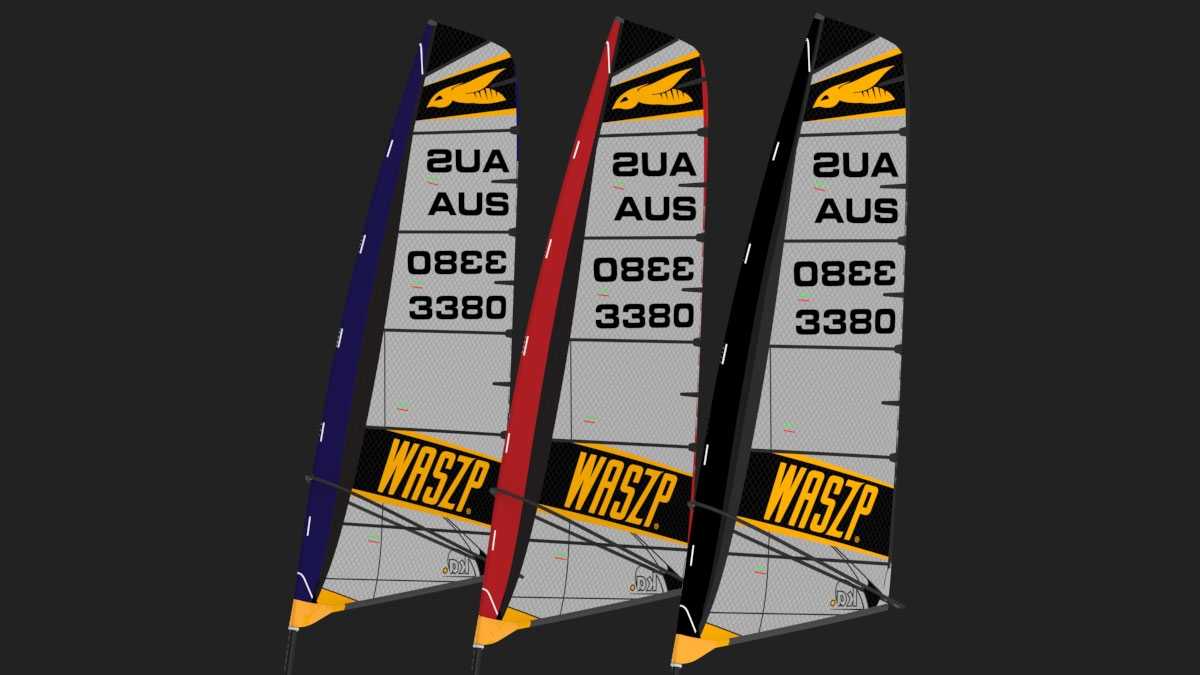

The upside also of this material is that the sail is more colourful, and on that note we have added coloured panels to the main body to make the sail really stand out.

Here is the 8.25 sq.m profile and graphics:

How about getting the rig up, are there still any issues there?

It’s now amazingly easy. As soon as we got the weight out of the rig everything changed but we wanted it to be fool proof. We redesigned the boom to mast attachment so the boom can be connected once the mast is up.

With just the mast and sail all the issues are gone.

And the trolley ?

We have continued to work hard on the trolley and we now have a hybrid solution.

You can tip the boat on its side and attach the trolley which some people will prefer to do. This is what I like as it suits where we sail at Black Rock and it works well.

But we have also incorporated a ‘shallow’ trolley design which means you can float it onto the trolley.

It becomes a little challenging in a lot of wind and waves, but very do-able. And the way which we are now attaching the trolley to the boat stabilizes everything once it’s on and makes for a very solid solution.

I think the big gain with the WASZP over the Moth is just to be able to wheel the boat in and out with the foils in. It really is so much nicer than the Moth where foils have to be separated.

You just wheel the boat up, detach the boom, pull the mast down, roll the sail and it’s done.

So that leaves the question of production and pricing?

It has been a long road to get a final price on this boat and this week we have finalized all negotiations.

We are very happy to confirm we can meet the price we originally estimated.

The ex-factory price will be US$11,900 with a shipping cost to most countries of US$1,100.

Local import costs, taxes and duties, if any, are additional and vary by country.

There will be few countries that the shipping costs is cheaper and in some countries that are harder to get to the shipping cost will be more expensive.

And what’s happening at the factory - are we still on track to start production in March?

We have already started production - we are building hulls, we are building masts, we are building sails, we are building plastic components and we are building aluminum foils. Hopefully everything will come together by the end of March and will start putting complete boats together.

I’m off to China again in a few days and will be back over again towards the later part of March to oversee the final packing.

So notwithstanding any delivery issues with a critical component, we will be shipping as promised.

How about the class set-up, any action there ?

We’ve been making good progress on drafting the WASZP Class rules.

Overall, the intent is to make sure we have a very strict one-design so that it is a true boat vs. boat contest straight out of the box.

So with the exception of changing out ropes or pulleys that may need replacement with aftermarket alternatives, adding a GPS and doing repairs back to original there is not much else that can be done that will not be ‘as supplied’.

A draft will soon be available to download for review and comment.

AUS / NZReseller

AUS / NZReseller USAReseller

USAReseller UKReseller

UKReseller ITReseller

ITReseller Global Ordering and Delivery

Global Ordering and Delivery