"TAKING FLIGHT" is a documentary displaying the essence of the WASZP Class and its journey to where it is today as the most popular one design foiling boat in the world.

The documentary takes you on a journey from the thought process in 2016 when the WASZP was launched, to the development of the WASZP Games, to the sailors experience, to the culture and the team behind the scenes. It is a gripping tale of how the WASZP plans to drive the future of sailing.

ABOUT THE WASZP

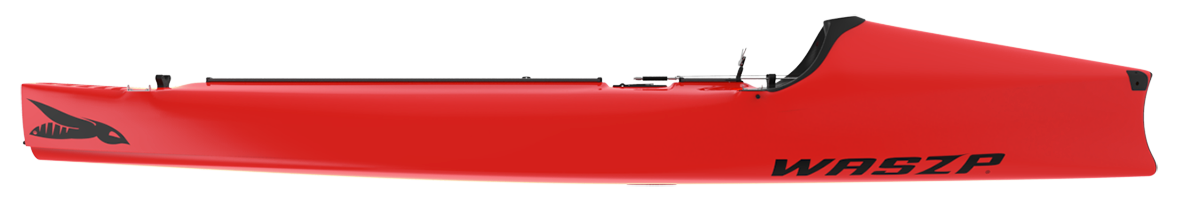

HULL

The hull is designed with a hollow nose area to cater for the intended sailor weight range: 40 kg to 95 kg. The heavier sailor can bury the nose without creating extra drag while the lighter sailor does not lose waterline length. The very strong low riding performance helps the transition to getting on the foils.

The forward curvature allows the wand connection to be brought forward for better response in waves. It also provides greater volume forward when bearing away to reduce accidental burying.

The stern is more voluminous to help in low speed manoeuvres are most likely to result the stern sinking.

It also enables the sailor to go aft to put the rudder up and down.

The licensed builder of the WASZP is the renowned McConaghy Boats China team (builder of the Mach2). McConaghy built the Elliot 6 used in the 2012 Olympics and has been inspected by World Sailing for that project.

CNC machine milled moulds and tightly controlled manufacturing systems are used to ensure uniformity in tolerance, hull stiffness, finish and weight in line with strict one design principles.

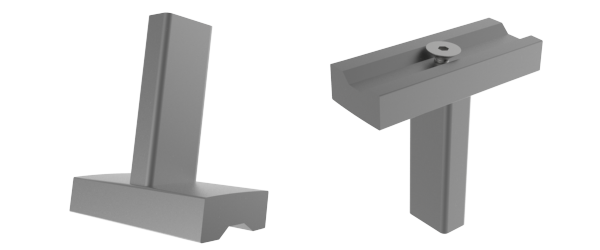

Finishing Jigs are used to positions frames, mast socket, center case and fixing points, then accurately positions the two halves as they are glued together.

The Jigs are made from machined alloy with a composite female bed to hold the hull. They are bolted to the floor for stability and calibrated from a master hull for repeatability. They ensure that everything is 100% accurate and every WASZP hull is exactly the same.

The hull is built with an infused epoxy system using a high density infused core to give a bullet-proof shell that will not dent with a hammer blow. Stiffness is obtained from the organic curves of the hull along an extensive framing system.

The centre seam enables 100% positive fixing of all internal frames and a bullet-proof join.

The frames interlock via a tongue and groove system when the two halves are sealed.

The nose area (front few cm’s) is made from polypropylene for impact resistance.

The fittings and control systems are a combination of custom design or best of breed from suppliers such as at Harken or Ronstan.

An integrated mount for GPS devices is included - SAILMON MAX is our device of choice, delivering faster sailors!

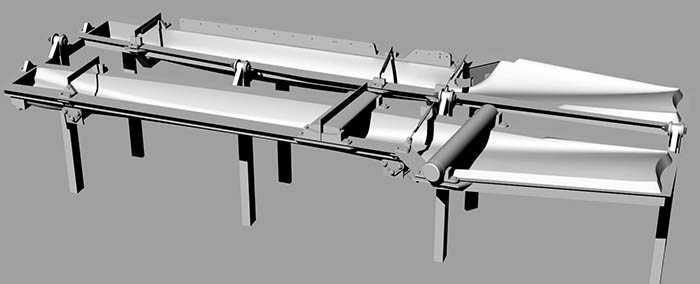

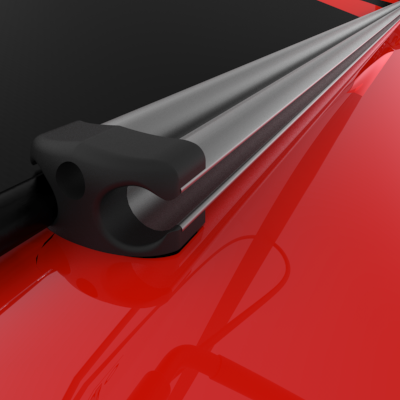

WINGS

To deliver the promise of foiling for first timers through to advanced racers, the orientation of the wings of the WASZP needed to be flexible to change the amount of stability provided to the sailor.

In addition, to overcome the challenge of storage somehow the width of the WASZP needed to be significantly reduced when in the boat park or at home.

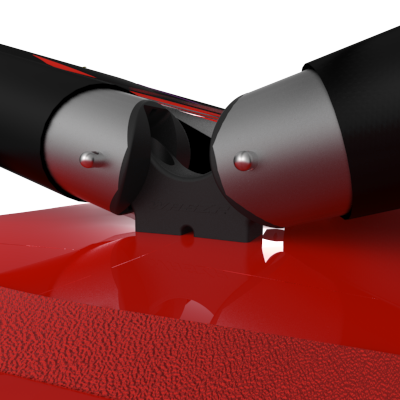

The Solution - the WASZP Hinged Wing System

By articulating the wings on the inner deck in combination with an adjustment system at the outer gunwhale.

The orientation can be changed quickly and easily changing the supplied wing supports.

A pin system securely locks the wings into their chosen mode.

WASZP MODES

STORAGE MODE

In storage mode the wings are folded vertically upwards.

This reduces the hull width to just over 1.4 m including the trolley.

The sail, mast and boom can all fit neatly inside the slot between the wings for storage.

Further gains can be made if the boats are parked top to tail.

LEARN MODE

In Learn mode the wings are locked down to a horizontal position.

This provides the most stable platform for learning to foil as the wing buoyancy is lowest to the water.

It also reduces the need for active balancing to keep the boat upright.

Movement around the boat is also easier on the flat surface.

Learn mode allows the sailor to concentrate on learning the balance and trim positions to initiate and sustain foiling.

RACE MODE

Once confident and consistently enjoying the rush of flying, moving to race mode lifts the wings to a 17-degree angle, allowing more advanced foiling techniques such as windward heel.

As the wings are further from the water this induces extra drive from the horizontal foils and increased righting leverage. This increases speed and height upwind significantly.

The wings tubes are 6061 aluminium tube with high strength plastic connectors.

The WASZP tramps slot into tracks built into the hull.

The tramps feature an integrated low drag flotation bladder that delivers positive buoyancy to provide a highly stable platform.

Tramps include a forward storage pocket and integrated holders for drink bottles in easy reach to the rear of the tramps.

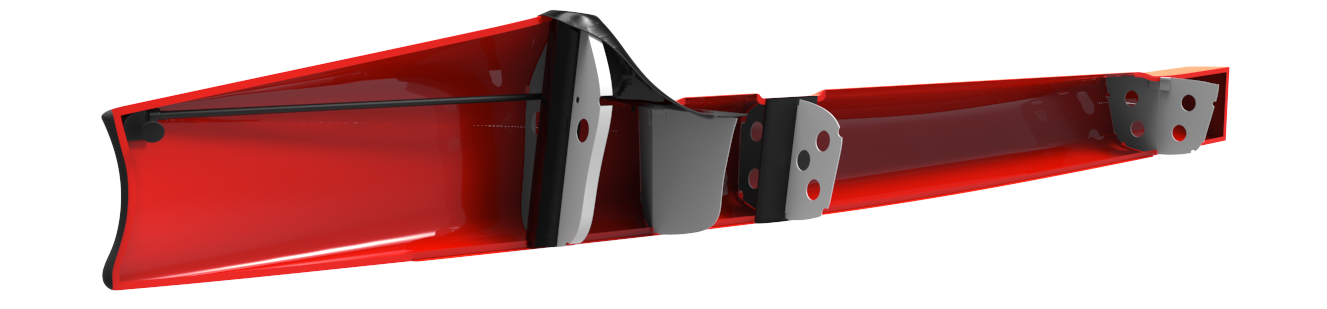

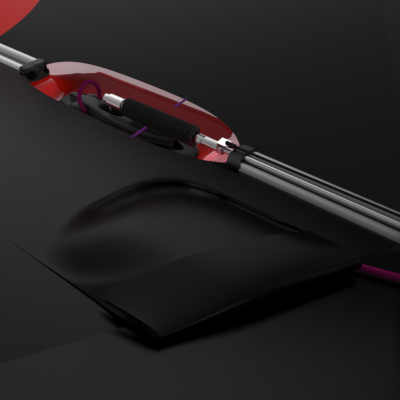

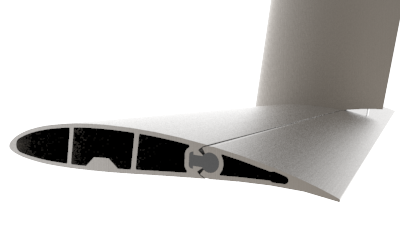

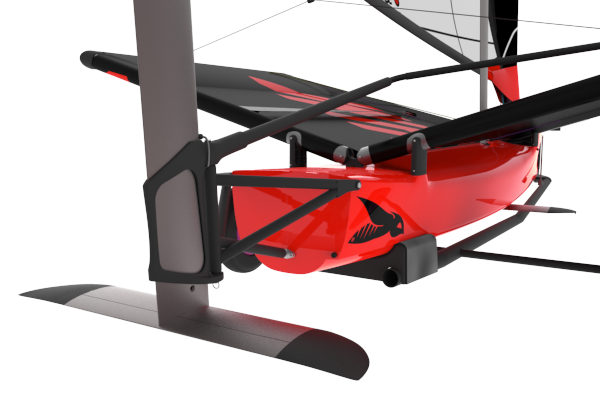

FOILS

Extensive design work was undertaken to develop foil sections that maximised all round performance with early lift-off and control through a wide wind range.

The vertical sections have come from proven low ventilation sections used on the Mach2 Moth.

The horizontals are a hybrid of high speed sections proven in the Mach2 and low speed, high tolerance sections used in the latest low wind Mach2 foils.

The centre board and rudder verticals and the horizontal foils of the WASZP are made from 6061-T6 aluminium.

Aluminium was seen as the only choice for the WASZP after experience in building more than 2,000 composite foils we realised that there was too much skilled workmanship required that meant inconsistency in foil production and finish.

With the WASZP our overriding mission was to be 101% consistent to enable racing by sailor merit rather than tweaking.

We also required that the foils were not sharp for safety and longevity.

6061-T6 was chosen because it is the strongest marine compatible grade (with higher tensile aluminium’s being too susceptible to corrosion). It is also more durable and able to withstand greater wear and tear.

Foils Down

Foils Retracted

Both the centre and rudder foils are fully retractable meaning launching is easy and safe.

A titanium joiner provides the load bearing strength for the interface between the horizontal and vertical.

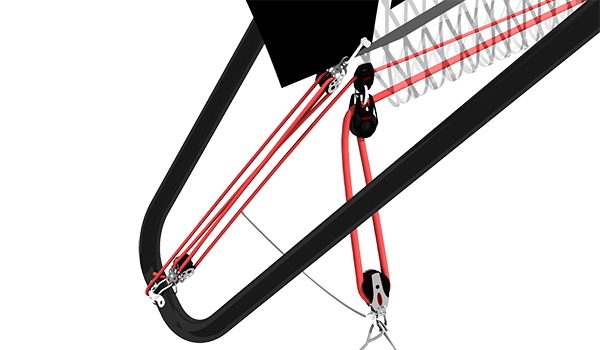

The main foil has an integrated flap controlled by a simple and robust mechanical sensor system driven by a fibreglass rod wand.

The foil control system of the WASZP is born from many years experimentation on the Moth combining adjustability with simplified ease of use.

Cast aluminium is utilised for the rudder box. A custom tiller extension made from aluminium with non-slip covering completes the rudder assembly.

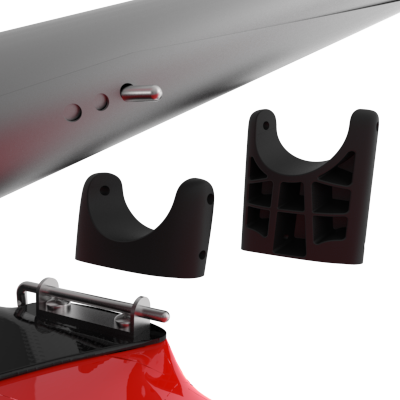

WING TIPS

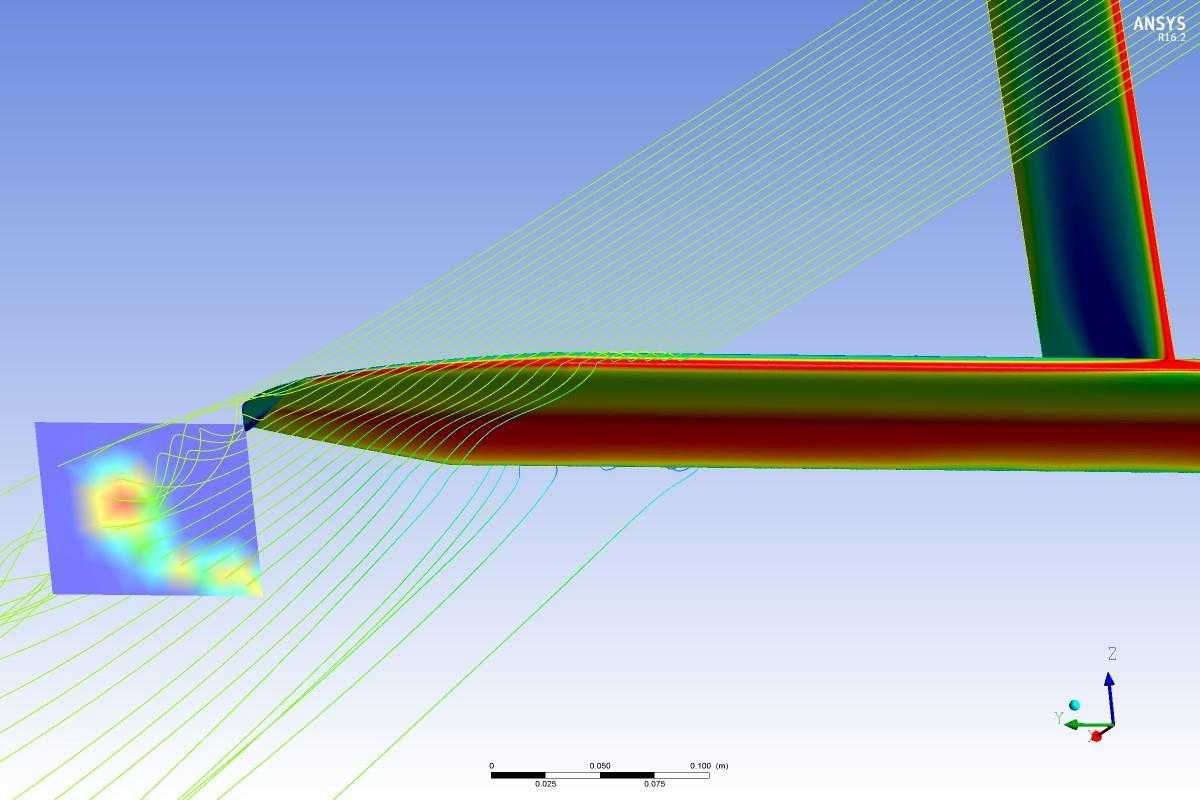

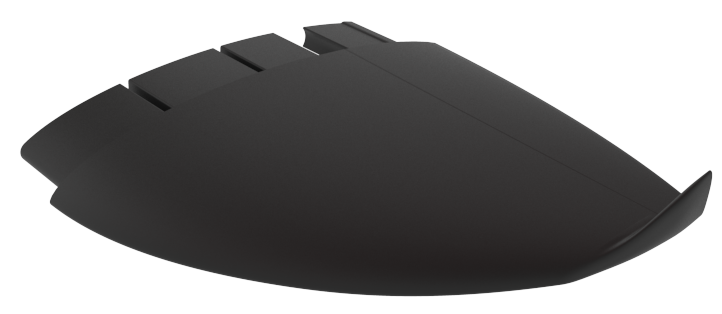

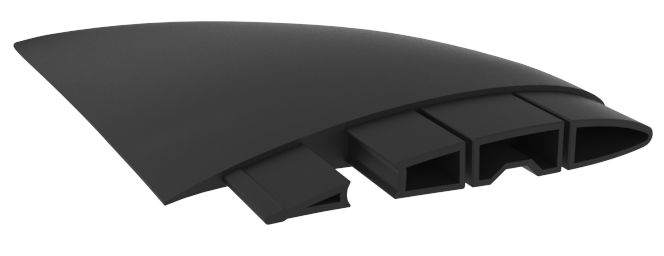

Significant time and effort went into resolving the final design including extensive CFD (computational fluid dynamics) analysis and testing on various wing tip and winglet versions.

The final main foil wing tip has small winglets and a short taper from the end of the aluminium – about 130mm of wing tip.

With the rear foil it’s very similar, except no winglets or articulated flap.

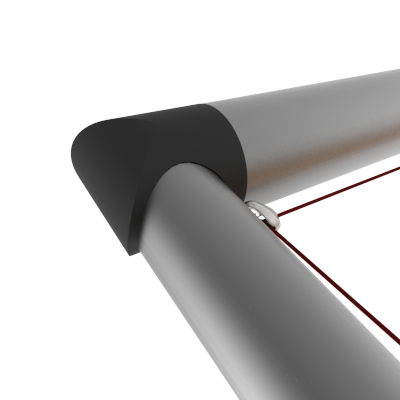

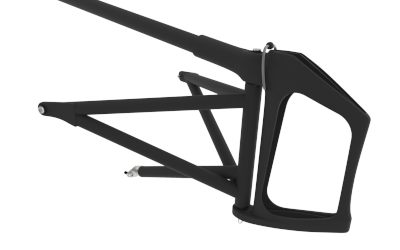

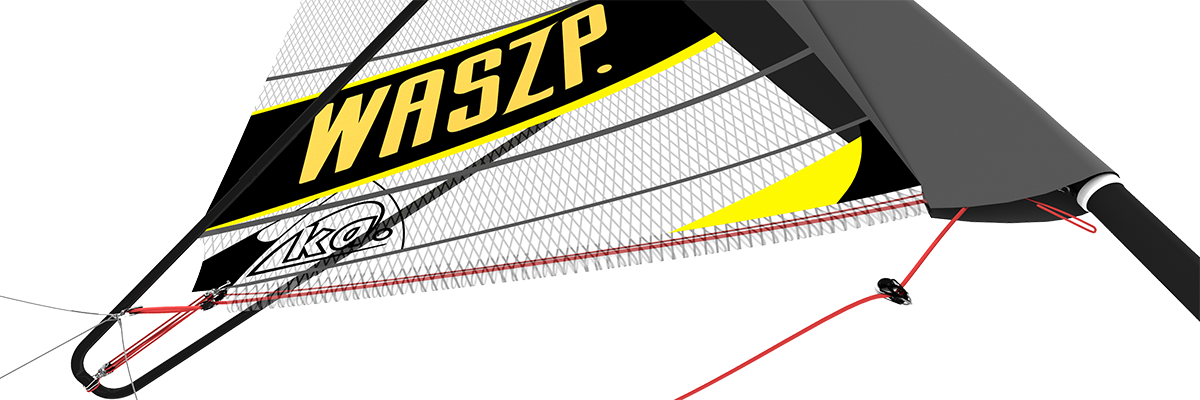

RIG

Optimising ease of rigging, simple tuning and effective performance across a wide wind range was the brief for the WASZP rig.

In addition, allowing for the foils to remain in place on shore meant a normal boom height was out of the question.

Finally, removing the potential dangers of a low boom and potential injury for crashing into stays meant a complete rethink was required.

The result – an unstayed, high performance sail with a wishbone boom that does not require a boom vang.

The sail is end boom sheeted with mainsheet and outhaul running forward through an integrated pocket built into the foot of the sail. The mainsheet is then led back to a block on the centreline.

All controls for Cunningham (downhaul) and foot tensioning (outhaul) terminate at the base of the mast support area for easy reach.

AUS / NZReseller

AUS / NZReseller USAReseller

USAReseller UKReseller

UKReseller ITReseller

ITReseller Global Ordering and Delivery

Global Ordering and Delivery